By Philip Haldiman

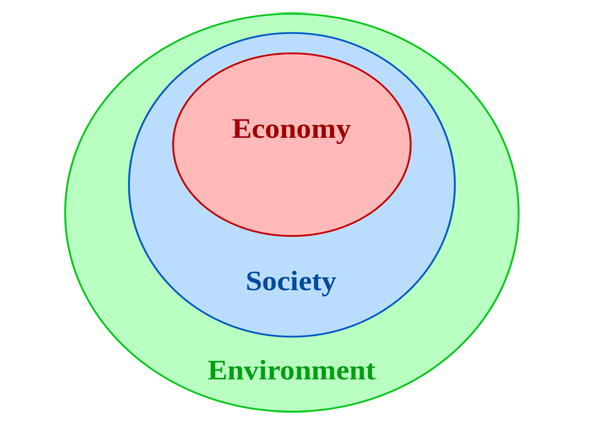

In the worst possible scenario, sustainability is survival. In the best possible scenario, it is thriving. So, if you are a business, would you rather survive or thrive?

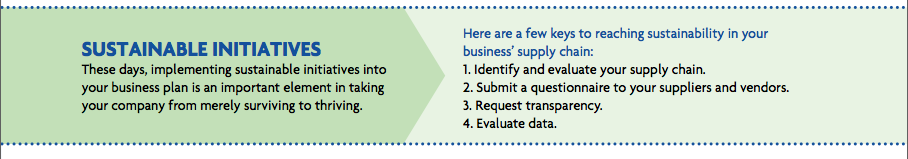

Of course, that is a rhetorical question. Sustainability can lead to efficiency, growth, brand recognition and innovation, not to mention cost reductions. Adding sustainable initiatives to your business plan is becoming increasingly necessary if the goal is to see your company thrive.

Tad Radzinski, president of Sustainable Solutions Corporations, knows these things well. It is his job to help companies reach their goals of sustainability. His clients include Waste Management, Merck, and Bosch and Philips.

For a company first starting out in making their business sustainable, says Radzinski, they must identify and evaluate their supply chain. This can be as simple as sending in a questionnaire to your suppliers or vendors specifically identifying your company’s needs.

“This data is valuable for many things. Manufacturers can use it in the development of new products. Maybe to reduce carbon footprint or greenhouse gas emissions,” Radzinski said. “But if you are a hotel chain or restaurant, then you have different needs. Are [your suppliers] providing you with products from recycled content? How are they transporting goods and services? This information helps with sustainability of operations.”

Data gleaned from a questionnaire is also really valuable for understanding risk, he said.

“Maybe you only have one supplier,” said Radzinski. “We had a client that was buying products from a single supplier in China and a tsunami hit, and suddenly they didn’t have that supply chain anymore. Being aware of that is important. ‘Wow, we only have one supplier, and that is a big risk to us. What are we going to do to minimize the risk or impact of that?’” Manufacturers also need to be in compliance with regulations, especially for companies with operations across many countries and jurisdictions. With more governmental regulatory agencies that oversee many industries and increased global regulations, compliance has become a bigger concern than ever before.

Radzinski said if a company is not compliant with regulations, it could get hit with significant fines. “If you are making products that are required to meet certain regulations, you need to make sure the parts, materials and products that the suppliers are sending you are in compliance with those requirements,” Radzinski said.

Obtaining such information about your supply chains might not be easy. He said transparency from suppliers is key, but some may be hesitant to share information or consider certain things proprietary.

“This happens quite often,” Radzinski said. “The best thing to do is educate them on the fact that if they supply this data, it will most likely benefit them because whoever is asking for it is probably going to sell more product, which is going to mean they will sell more materials.”

Philip Haldiman is a journalist, artist, cult film star and Phoenix native.

Read more business articles at greenlivingaz.com/business