BY ANGELA FAIRHURST

In an era marked by mounting plastic waste and its devastating effects on the environment, a groundbreaking innovation from Japan’s RIKEN Center for Emergent Matter Science (CEMS) offers a glimmer of hope.

Led by Takuzo Aida, the team has engineered a durable, yet biodegradable plastic that breaks down in seawater, potentially eliminating the scourge of microplastics that have been infiltrating our marine ecosystems and food chains. This innovative material, detailed in a recent scientific publication, stands to transform the landscape of sustainable materials and global pollution.

THE HIDDEN POWER OF SEAWATER

Traditional plastics have long been a double-edged sword. While versatile and durable, their non-biodegradable nature has led to widespread environmental contamination. Even biodegradable alternatives like PLA (polylactic acid) fall to break down in marine environments, contributing to the accumulation of harmful microplastics — particles that range from one nanometer to five millimeters in size — that harm aquatic life and find their way into human food chains.

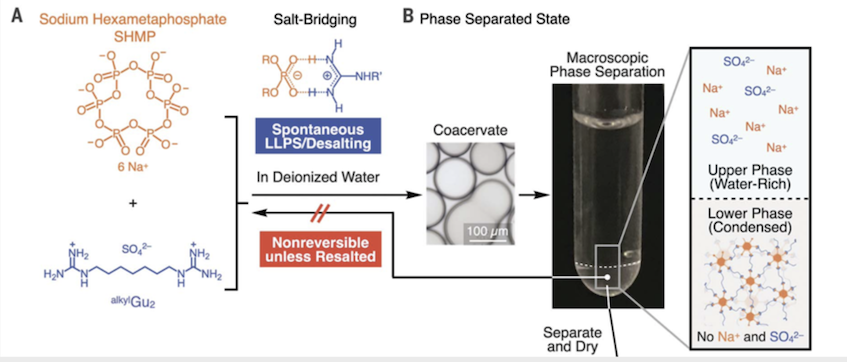

The secret behind this new material lies in its innovative chemical composition. By combining two ionic monomers to form cross-linked salt bridges, the researchers have created a plastic that is both strong and flexible. Initial experiments used sodium hexametaphosphate, a common food additive, and guanidinium ion-based monomers, both of which can be metabolized by bacteria. When the plastic dissolves in soil, it leaves behind phosphorus and nitrogen, enriching the earth as a fertilizer.

In trials, the new plastic degraded completely in soil within 10 days, a sharp contrast to conventional plastics that persist for centuries. Even more impressively, these materials break down entirely in seawater, eliminating the risk of microplastic pollution in our oceans. “While the reversible nature of the bonds in supramolecular plastics has been thought to make them weak and unstable,” says Aida. “Our new materials are just the opposite.”

The material’s salt bridge structure ensures stability unless exposed to electrolytes like those in seawater, which triggers degradation. “With this new material, we have created a new family of plastics that are strong, stable, recyclable, can serve multiple functions, and, importantly, do not generate microplastics,” says Aida.

A VERSATILE PLASTIC FOR EVERY NEED

The RIKEN team’s breakthrough goes beyond environmental sustainability. This new family of plastics can be tailored to exhibit various degrees of hardness and tensile strength. Whether for hard, scratch-resistant applications or soft, flexible uses, the material’s performance rivals or exceeds that of conventional plastics.

(A) Molecular structures of SHMP (orange) and a guanidinium sulfate (Gu) -based monomer. (B) Spontaneous liquid-liquid separation after mixing aqueous solutions of the monomers. The upper liquid is water-rich, containing sodium and sulphate ions, while the lower liquid is viscous and contains the 3D cross-linked supramolecular polymer.

(A) Molecular structures of SHMP (orange) and a guanidinium sulfate (Gu) -based monomer. (B) Spontaneous liquid-liquid separation after mixing aqueous solutions of the monomers. The upper liquid is water-rich, containing sodium and sulphate ions, while the lower liquid is viscous and contains the 3D cross-linked supramolecular polymer.

By testing different types of guanidinium sulfates, the researchers generated plastics suitable for diverse applications, including hard, weight-bearing structures, rubber-like textures, and even materials for 3D printing and medical devices. Additionally, the material is non-toxic, non-flammable, and can be reshaped at temperatures of about 120°C making it a viable alternative to traditional thermoplastics.

The team also recovered 91% of the hexametaphosphate and 82% of the guanidinium as powders after dissolving the plastic in salt water, which indicates that recycling is easy and efficient with the new material. This opens possibilities for reducing waste in industrial and consumer settings.

HOPE FOR CLEANER OCEANS

This innovative material represents a significant leap forward in sustainable plastics technology. Imagine a future where grocery bags, food packaging, and medical devices contribute to the health of our planet rather than harming it. By addressing the critical issue of microplastic pollution and recyclability while maintaining the versatility and strength of traditional plastics, Aida and his team have opened new possibilities for environmentally responsible material use across a multitude of industries.